New insights in metamaterials lead to better implants, robot hands, and bumpers

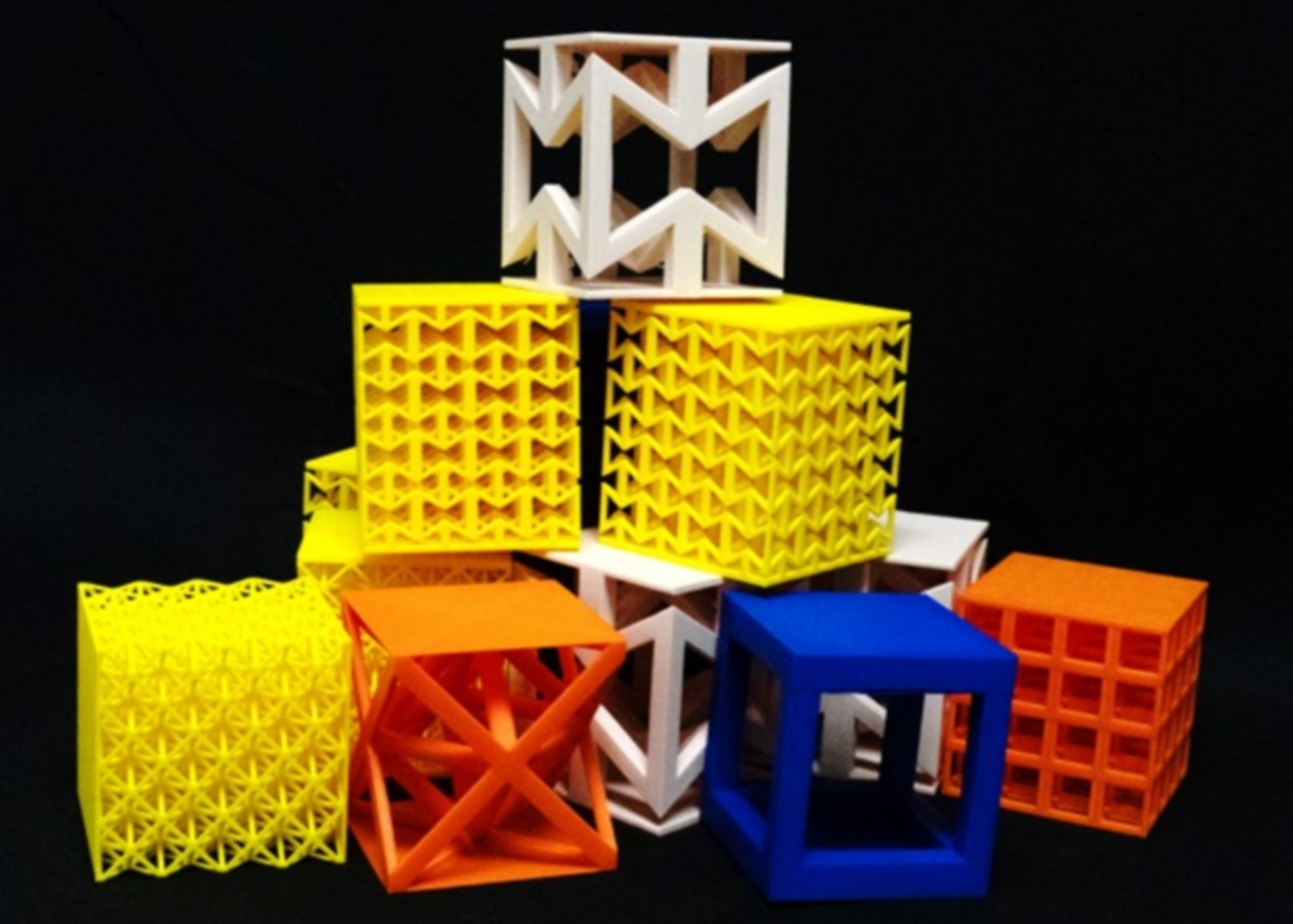

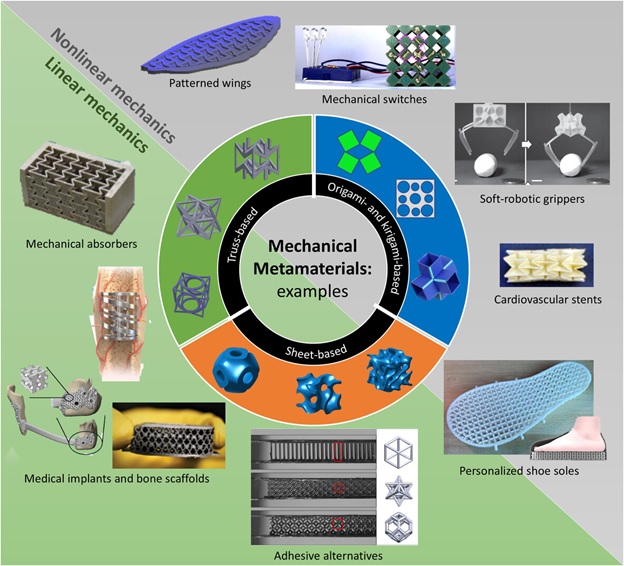

Metamaterials are composites with a very precisely controlled structure. It is this structure that determines the properties of the metamaterial, not the substances it is made of. Typically, a metamaterial consists of repeating identical blocks called unit cells. New research by PhD student Shyam Veluvali, Prof. Anastasiia Krushynska, and colleagues from the University of Groningen, UMCG, and Karlstad University in Sweden shows that the overall mechanical response of metamaterials depends on how many unit cells are joined together, and how they are arranged.

FSE Science Newsroom | René Fransen

In their paper in the journal Small Structures, Veluvali and colleagues show how the size of the building blocks affects the simplest behaviour, such as elasticity. They also show that the number of blocks can affect the metamaterial properties. Furthermore, the more blocks are added, the easier it becomes to predict the structural behaviour of a metamaterial. These insights help to predict the mechanics of metamaterials, such as bone implants, with higher precision.

A metamaterial alternative

Currently, bone implants are made of a titanium alloy, which is much stiffer than the bone itself and, therefore, takes most of the load from chewing or talking. The stiff titanium reduces the load on the remaining bone and, as the bone adapts to this load, weakens it. ‘We propose to replace traditional implants with a metamaterial alternative,’ says Veluvali. By adapting the material’s structure, it is possible to match the stiffness of the implant to that of the bone. In that case, the bone and the implant share the load and, consequently, the bone remains strong.

The paper also shows that it matters what type of force is acting on the metamaterial. Veluvali: ‘We found that different kinds of forces, such as shear, stretching, or torsion, can have different effects on the same material.’ This was not yet known, as prior studies focused on just a single force.

All these results are useful for the design of different types of implants (e.g. orthopaedic or spinal), and also of applications such as the grippers of robotic hands or energy absorbers such as car bumpers. ‘Our insights help to design safer, longer-lasting structures for various applications by choosing the right block size and arrangement.’

Reference: H.C.V.M. Shyam Veluvali et al.: When Scale Matters: Size-Dependent Mechanics of Architected Lattices for Implants and Beyond. Small Structures, 13 January 2026

More news

-

29 January 2026

Microplastic research - media hype or real danger?

-

27 January 2026

ERC Proof of Concept grant for Maria Loi