Atomistic model explains how memory alloys can change their shape

Shape memory alloys are exotic materials that can be deformed at room temperature and return to their ‘remembered’, pre-deformed shape when heated. They are used in a broad range of applications such as heart stents, dental braces, actuators that move wing flaps, and energy harvesting. Mechanical engineer Francesco Maresca and his team from the University of Groningen have worked out how memory metals change shape at the atomic level.

FSE Science Newsroom | René Fransen

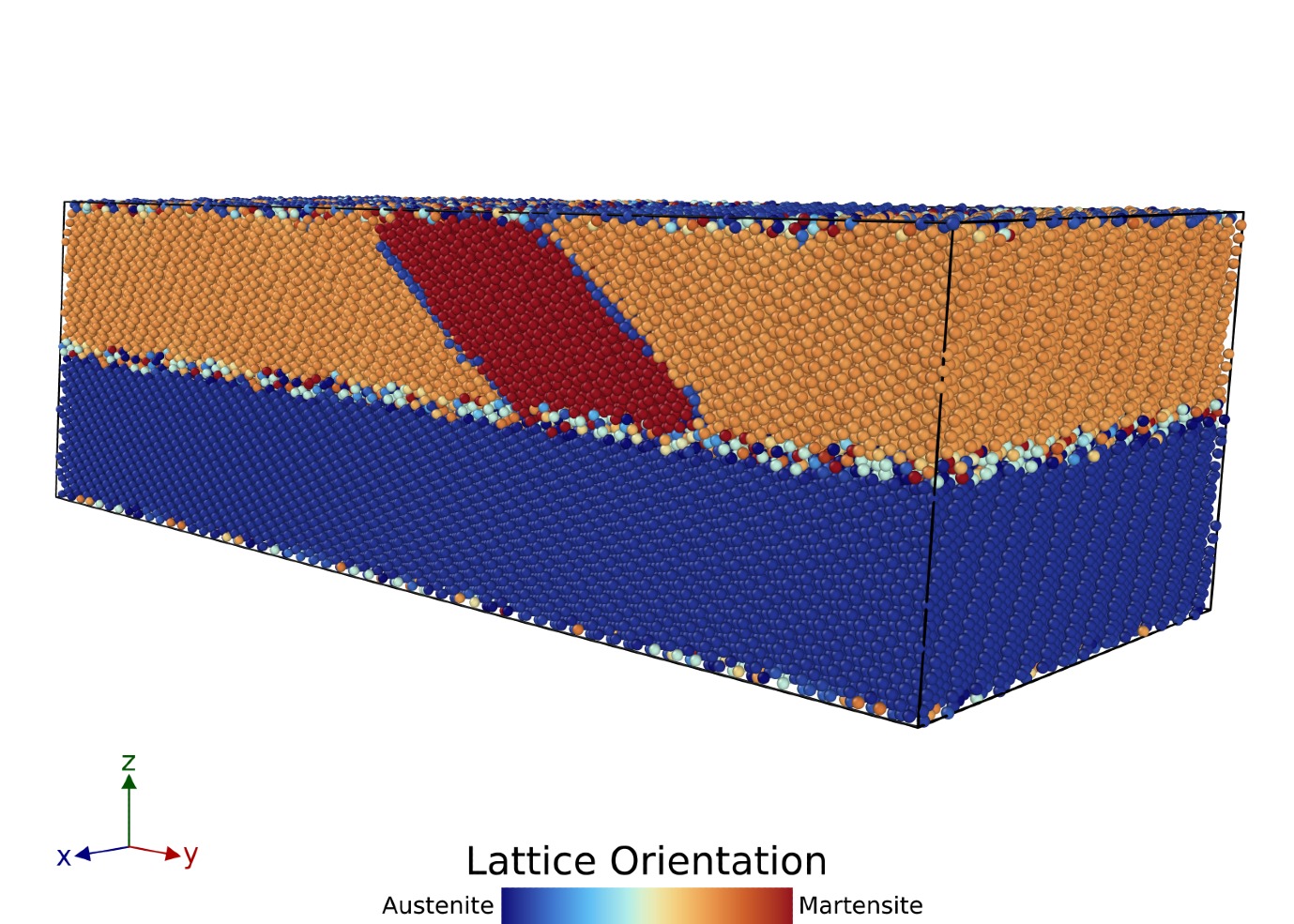

The key properties of shape memory alloys are the shape memory effect and superelasticity, both of which are controlled by ‘microstructural twinning’. This is a highly symmetrical arrangement of the material at the atomic scale, in which domains of two mirror-image crystal structures form. The reversible movement of these twin interfaces through the material enables effortless shape change. Maresca: ‘Knowing which types of twins form and which applied force drives their formation is crucial to designing engineering components such as actuators or dental braces.’

Modelling memory alloys

However, how this movement occurs at the atomic scale was not yet known. Using a range of techniques, including machine learning, materials theory, and computational physics, Maresca’s team developed a model that was able to highly accurately predict the driving force for the formation of these twins, close to the quantum mechanical level. The new model explains what makes microstructural twinning happen and goes against established understanding.

This new approach is expected to revolutionize the way shape memory alloys are modelled, expects Dr Lorenzo La Rosa, a member of Maresca’s team who led the twin modelling efforts: ‘Based on our model, better shape memory crystalline materials could be designed for applications that require reversible deformations, vibration damping, or impact absorption.’ The next step for the team is to predict the mechanical response at the engineering scale, based on their new findings. This will allow them to explore the potential for new shape memory compositions.

Maresca concludes: ‘What was exciting about this project is that it combined efforts of students and researchers at the crossroads of machine learning, materials science, and computational physics: a truly multidisciplinary effort.’

The findings were published online in the journal Acta Materialia on 30 October.

More news

-

17 February 2026

The long search for new physics

-

10 February 2026

Why only a small number of planets are suitable for life