Slimme robots om kleinere chips te maken

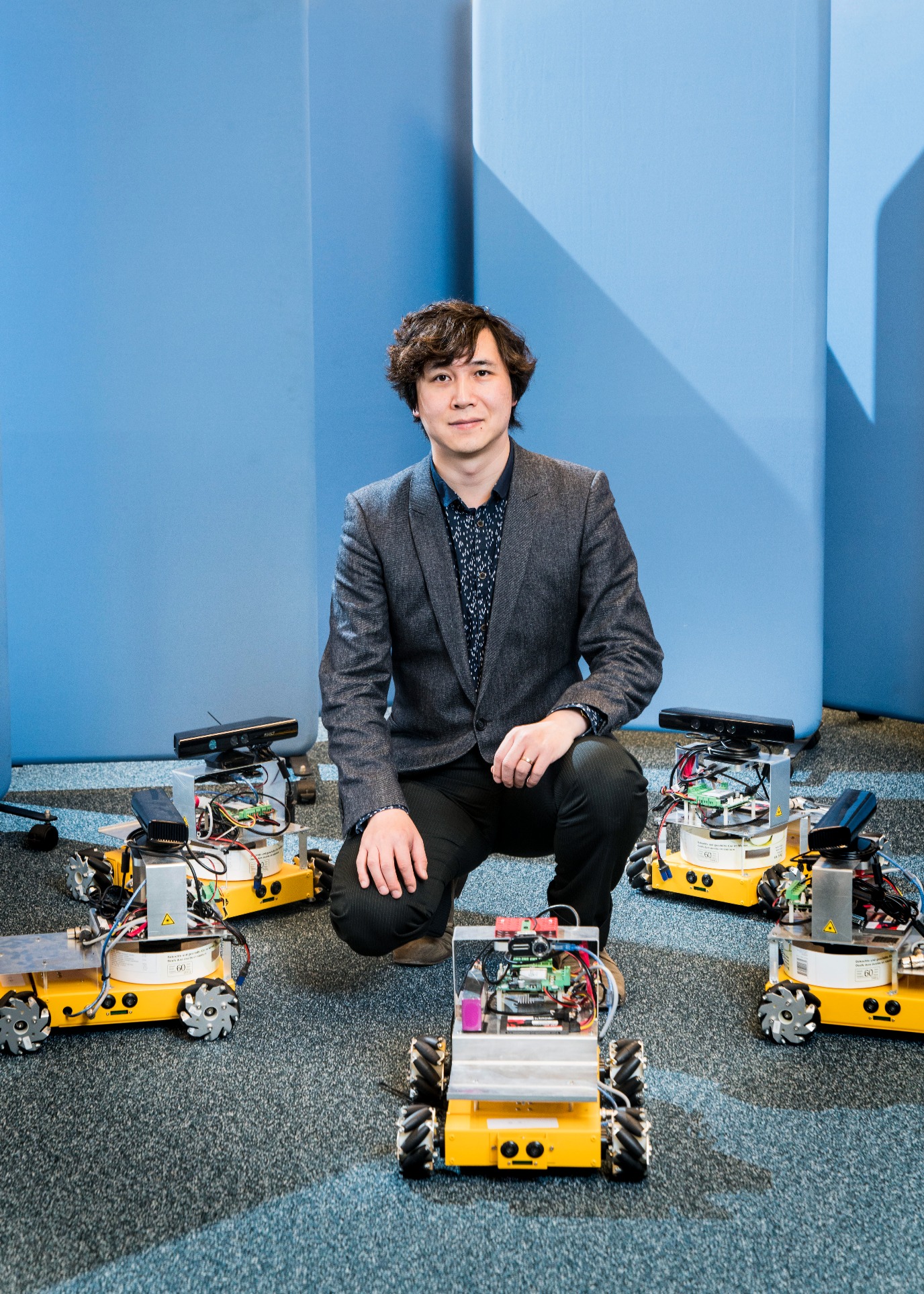

Een robotarm in een fabriek die herhaaldelijk dezelfde beweging maakt: dat is iets van het verleden, vindt Ming Cao, hoogleraar netwerken en robotica en directeur van de Jantina Tammes School of Digital Society, Technology and AI. ‘We gaan steeds meer toe naar smart industry , met robotarmen die zelf beslissingen kunnen maken.’ Verschillende wetenschappers van de Rijksuniversiteit Groningen werken samen met hightech bedrijven zoals chipfabrikant ASML om productieprocessen steeds meer autonoom te maken.

FSE Science Newsroom | Charlotte Vlek

‘Het maken van een chip is een volledig geautomatiseerd proces,’ vertelt Cao, ‘daar komt bijna geen mens meer aan te pas.’ Maar onze elektronica wordt steeds kleiner en kan steeds meer, waardoor de productie van chips nog nauwkeuriger moet. En dat betekent: de apparatuur die de chips produceert net even anders instellen bij de kleinste veranderingen in temperatuur of luchtvochtigheid in de fabriekshal. Cao: ‘Zoiets gaat de menselijke capaciteit te boven. Een sensor daarentegen, heeft een kleine verandering meteen opgepikt.’

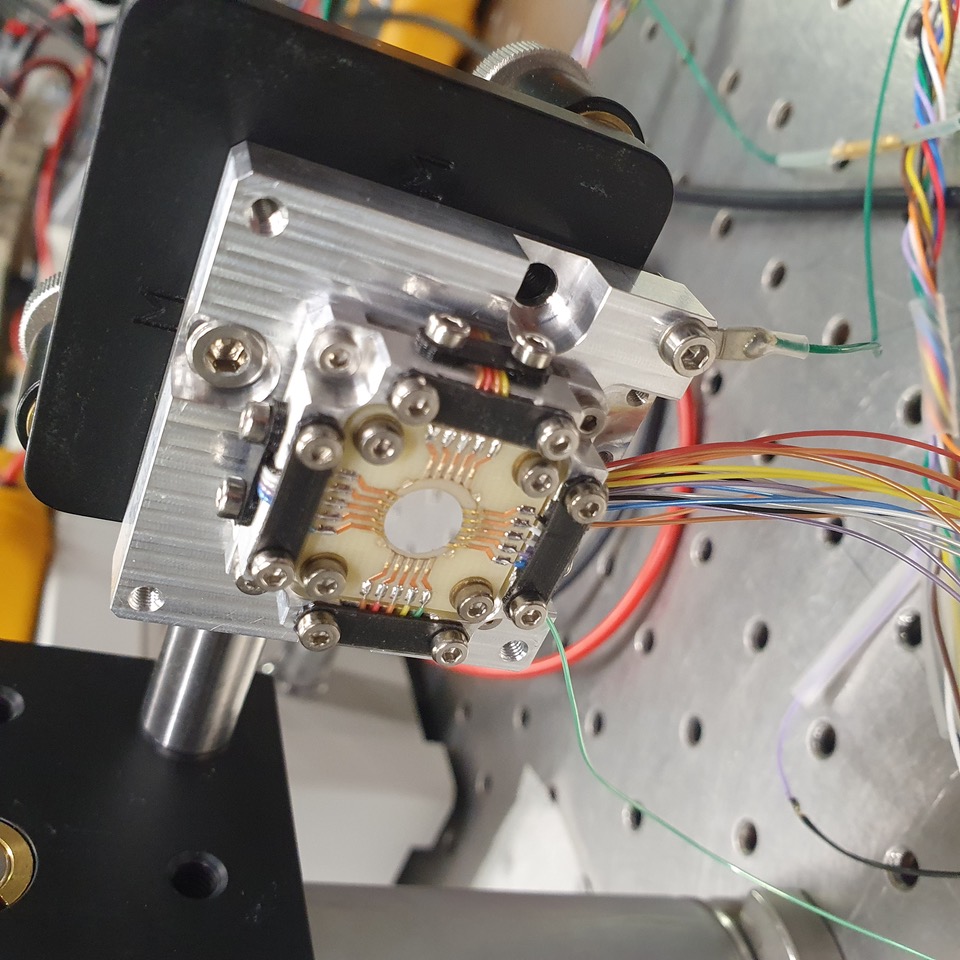

Een platte silicium wafer

Neem bijvoorbeeld het materiaal dat de basis vormt van een chip: silicium. Een dun silicium plaatje, een silicium wafer, ligt onder een laser die er lagen van onderling verbonden patronen op nanoschaal op aanbrengt. Het is van het grootste belang dat de silicium wafer netjes plat ligt, want zodra de laser wat schuin op het oppervlak valt, is de lichtbundel uit focus en geeft dat onnauwkeurigheden.

Daarom ontwikkelen Bayu Jayawardhana, hoogleraar mechatronica en controle van niet-lineaire systemen, en Mónica Acuautla Meneses, adjunct hoogleraar materialen voor mechantronische systemen, samen met chipfabrikant ASML een vervormbare wafer table waarop de silicium wafer perfect plat mee komt te liggen. Ze gebruiken daarvoor een piëzo-materiaal dat op een specifieke locatie uitzet wanneer daar een stroompje doorheen gaat. Daardoor kan elk stukje van de wafer table in hoogte worden aangepast.

Een vervormbare wafer table

Het idee kwam eigenlijk voort uit een eerder project van RUG-wetenschappers Jayawardhana en Acuautla met instrumentmakers van SRON, waarin ze een vervormbare spiegel ontwikkelden voor de observatie van exoplaneten. Het was belangrijk om lichtgolven uit de ruimte precies goed op de spiegel te laten vallen om een optimaal signaal te krijgen – vergelijkbaar met de laser van ASML die de silicium wafer nauwkeurig moet raken, al is dat op een veel kleinere schaal.

Om zo’n vervormbaar oppervlak te verkrijgen, gebruiken ze een piëzo-materiaal. Stroomdraadjes die aan het materiaal gekoppeld zijn zorgen voor een raster van ‘pixels’, zo dat elke pixel apart ingesteld worden op de gewenste hoogte. Jayawardhana houdt zich bezig met de berekeningen achter die aansturing. ‘De uitdaging zat vooral in de enorme hoeveelheid kabeltjes die nodig zouden zijn voor de aansturing,’ vertelt hij. Dat zou voor een stuk van honderd bij honderd pixels algauw uitkomen op 20.000 kabeltjes: twee per pixel, zodat ze allemaal tegelijk hun eigen stroompje toegediend kunnen krijgen.

Om het aantal kabeltjes te reduceren, maakt Jayawardhana slim gebruik van het ‘geheugen’ van het piëzo-materiaal, waardoor elke pixel apart ingesteld kan worden, de een na de ander. Op deze manier zijn er veel minder kabeltjes nodig – slechts 200. ‘Voor elke pixel meten we hoeveel spanning nodig is om tot de gewenste dikte te komen, we meten het daadwerkelijke effect en finetunen nog wat. Zo gaan we alles punt bij punt langs, tot de gewenste oppervlakte-vorm bereikt is.’

Componenten aan elkaar knopen

Zo’n wafer table is slechts één onderdeel van de machine die een chip maakt. Zo’n onderdeel wordt dan bijvoorbeeld gemaakt door een expert op het gebied van piëzo-materialen, terwijl een andere expert de algoritmes aanlevert om het geheel aan te sturen. Maar hoe zorg je dat al die verschillende experts onderdelen ontwikkelen die tenslotte ook samen doen wat ze moeten doen?

Een ingenieur van ASML weet misschien uit ervaring dat een component alleen onder bepaalde omstandigheden goed functioneert, maar wij brengen automatisering aan in het ontwerpproces

Bart Besselink, adjunct hoogleraar systeem- en regeltechniek werkt aan wiskundige methodes om dergelijke complexe systemen in onderdelen uit te splitsen. ‘Het kan dan gaan om complexe systemen zoals de machines in een chipfabriek, maar ook een zelfrijdende auto of een slim energiesysteem,’ vertelt Besselink. ‘Het kernidee is om op een wiskundig precieze manier te formuleren waar elk onderdeel aan moet voldoen.’

‘Een ingenieur van ASML weet misschien uit ervaring dat een component alleen onder bepaalde omstandigheden goed functioneert, maar wij brengen automatisering aan in het ontwerpproces.’ Dat maakt het mogelijk dat verschillende ontwerpteams daar goed over kunnen communiceren, en misschien zelfs onderhandelen over welk eisen absoluut belangrijk zijn, terwijl andere eisen misschien wel wat versoepeld kunnen worden.

Specificaties naar de industriële praktijk brengen

Autonome systemen combineren fysieke hardware met sensoren om metingen te doen, actuatoren die acties op gang kunnen brengen, en de bijbehorende software-laag die de boel moet aansturen. Elk onderdeel wordt ontwikkeld door een expert op dat gebied, zoals een software-ontwikkelaar voor de software, een technicus voor de sensors.

Om te zorgen dat elk onderdeel ook de juiste bijdrage levert aan het grotere systeem, moeten ze aan bepaalde eisen voldoen. ‘Vaak gaat het dan ook nog om dynamische eigenschappen,’ vertelt Besselink: ‘iets dat door de tijd heen verandert.’ Denk bijvoorbeeld aan temperatuurveranderingen in een chipfabriek of de snelheid van een autonome auto.

Door die veranderende eisen in formules te vatten, kan het ontwerp van zo’n systeem nauwkeurig worden uitgewerkt, wat weer garandeert dat het systeem zich naar behoren gedraagt. De volgende stap voor Besselink is om deze wiskundige ontwerp-hulp een stap dichter naar de industriële praktijk te brengen. Daarvoor gaat hij binnenkort samenwerken met verschillende bedrijven die de ontwerpmethodes in de praktijk gaan brengen.

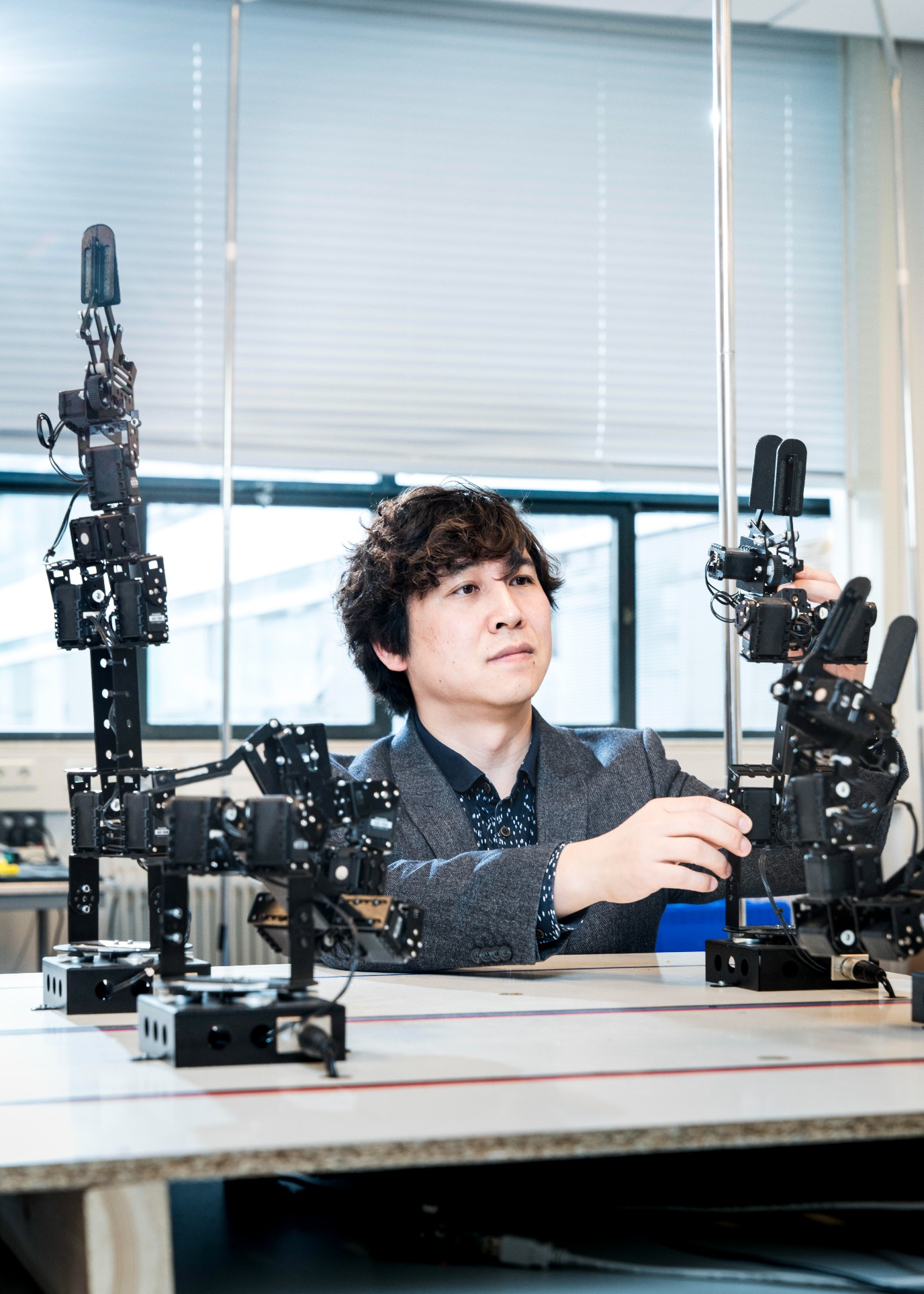

Samenwerkende robots

Het is net als met mensen. Er moet wel onderling vertrouwen zijn om te kunnen samenwerken.

Ook Ming Cao houdt zich bezig met verschillende onderdelen die moeten samenwerken. ‘Denk aan robots die een product samenstellen: de één verzamelt de benodigde materialen en de ander zet het in elkaar. Dan is het handig als ze informatie kunnen uitwisselen: bijvoorbeeld dat wanneer de eerste robot het gewicht van een onderdeel al weet, hij dat doorgeeft aan een volgende robot, die dan van deze informatie gebruik kan maken.’

‘Maar het is net als met mensen,’ voegt Cao toe: ‘er moet wel onderling vertrouwen zijn om te kunnen samenwerken.’ Want wat als de informatie van een naburige robot niet overeenkomt met de metingen van de eigen sensor? De robots van Cao onderhandelen dan met elkaar, en doen dat in milliseconden: ‘Het gaat daarbij om complexe situaties die in een korte tijd moeten worden beoordeeld, met weinig ruimte voor fouten. Zoals verschillende robotarmen die samen iets bouwen in een fabriek.’

Samenwerkende robots onder water en in de scheermesjes-fabriek

Sommige werkzaamheden zijn voor mensen nu eenmaal niet te doen, bijvoorbeeld het onderhoud van offshore windparken. Cao werkt samen met Fugro Innovation & Technology, om onderwater robots en oppervlakte-voertuiten te ontwikkelen voor windparken op zee. Die kunnen inspecteren of een windturbine nog naar behoren werkt, en of er bijvoorbeeld scheuren zitten. Cao: ‘De robots moeten dan samen beslissingen nemen, zoals: wie van ons gaat dit inspecteren; degene die het dichtstbij is, of degene met het hoogste batterijniveau?’

Cao werkt ook samen met Philips Drachten, om de productie van scheermesjes te automatiseren. Het doel is dat de fabriek niet steeds hetzelfde scheermesje produceert, maar dat dezelfde robotarmen verschillende typen mesje in elkaar kunnen zetten. Cao heeft vooral plezier in het onderzoek dat achter zo’n vraag vandaan komt: ‘Het is wetenschappelijk gezien een mooie uitdaging!’

Zo hoog mogelijk op de autonomie-ladder

Cao, Jayawardhana en Besselink werken alle drie aan autonome systemen in industriële toepassingen. Daarmee willen ze innovatie brengen naar de Nederlandse industrie. Dat doen ze binnenkort met het nieuwe samenwerkingsverband voor autonome systemen in Noord-Nederland: Infinitech, een ecosysteem om vragen vanuit bedrijven te koppelen aan oplossingen vanuit kennisinstellingen.

Jayawardhana geeft een voorbeeld: ‘Stel je verschillende niveaus van autonomie voor, als een soort ladder. Een auto met cruise control heeft een klein stapje gezet op de autonomie-ladder, en een volledig zelfrijdende auto zit het hoogst. Wij willen bedrijven zo hoog mogelijk op die autonomie-ladder brengen. Er zijn zoveel prachtige ideeën, de vraag is vooral welke toepassingen we daarvoor kunnen vinden.’

Vanaf september 2024 start de Rijksuniversiteit Groningen met het nieuwe Engineering Doctorate Autonomous Systems. Deelnemende trainees zullen zowel bij een bedrijf als bij de RUG werken aan technische oplossingen voor de automatisering van systemen in de hightech industrie.

Lees ook: ‘De chip van de toekomst’ (verschijnt volgende week)

Meer nieuws

-

17 februari 2026

De lange zoektocht naar nieuwe fysica

-

10 februari 2026

Waarom slechts een klein aantal planeten geschikt is voor leven