Hoe een tegendraads idee recycling van rubber mogelijk maakt

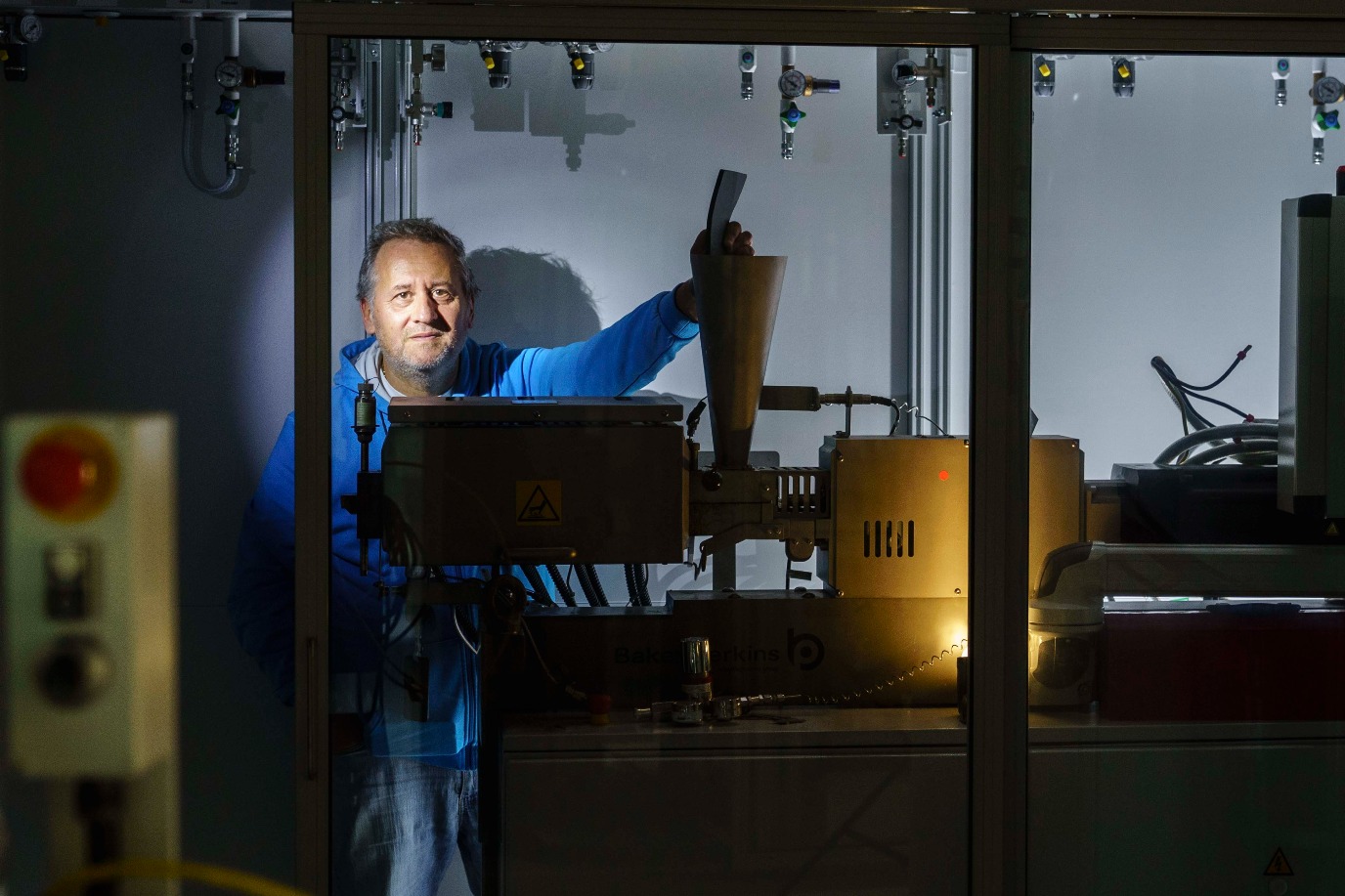

Een klein bedrijf in Grootegast maakt fietsmandjes en slippers van gerecycled rubber. Dat is bijzonder, want tot voor kort was het onmogelijk rubber opnieuw te gebruiken. Totdat hoogleraar Chemische Technologie aan de RUG Francesco Picchioni, samen met emeritus Ton Broekhuis, ontdekte hoe dat wel kan.

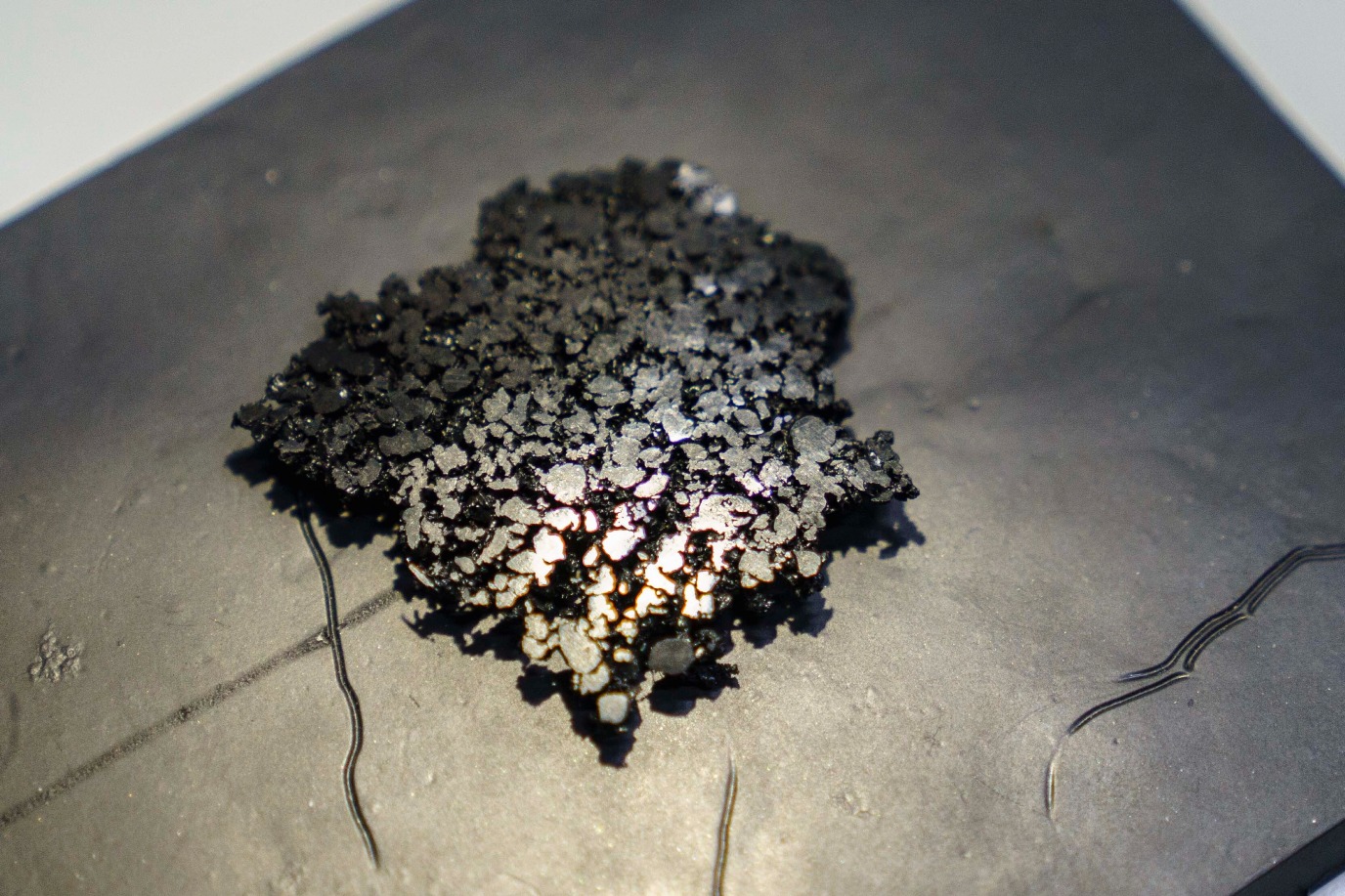

Rubber – zowel natuurlijk als synthetisch – begint als een kleverige, stroperige vloeistof die bestaat uit lange, spaghetti-achtige moleculen. In de 19e eeuw ontdekte Charles Goodyear een manier om deze vloeistof om te zetten in rubber zoals we dat nu kennen, door de spaghettislierten aan elkaar te verbinden met zogeheten zwavelbruggen. Dit proces heet vulkanisatie. ‘Wanneer de slierten op deze manier verbonden zijn is hun bewegingsvrijheid beperkt, waardoor de vloeistof verandert in een elastische vaste stof,’ legt Picchioni uit.

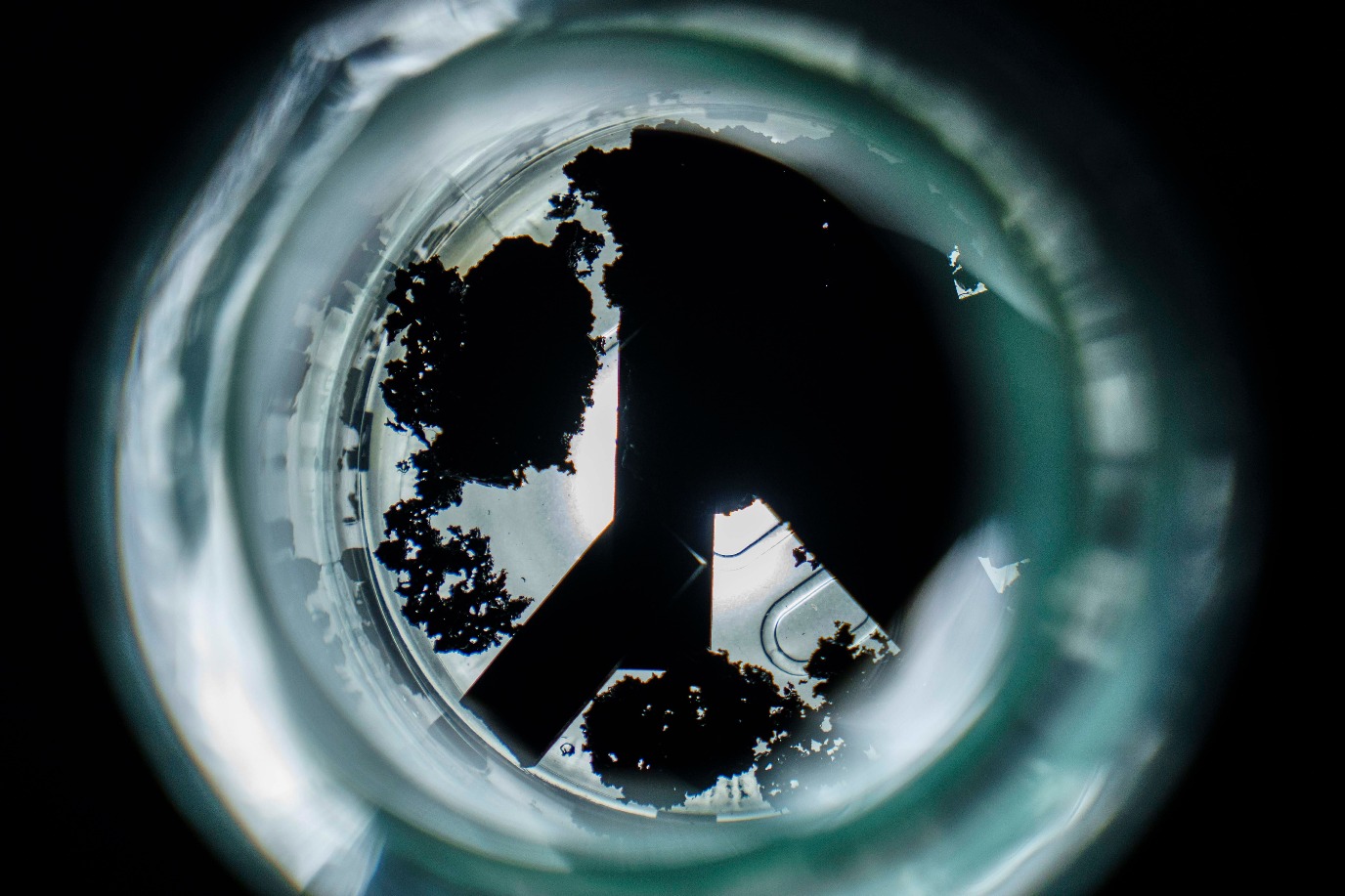

Om oud rubber opnieuw te gebruiken moeten die zwavelbruggen verbroken worden. Dat is lastig, omdat daardoor ook breuken ontstaan in de spaghettislierten. En kortere slierten zorgen voor een lagere kwaliteit rubber. Daarom zoeken wetenschappers overal naar een methode die de zwavelbruggen afbreekt, maar de slierten zoveel mogelijk intact laat.

Picchioni bezag wat zijn collega’s allemaal probeerden en besloot om een totaal andere richting in te gaan. ‘Ik ben nogal tegendraads,’ zegt hij. ‘Als iedereen rechtsaf slaat wil ik weten wat er gebeurt wanneer ik naar links ga.’ Hij besloot om de ‘spaghetti’ gewoon in stukjes te breken met een mechanische techniek, waardoor er korte slierten ontstonden. Vervolgens voegde hij een stofje toe dat deze korte stukjes op een willekeurige manier aan elkaar plakt. ‘Dat leverde een plakkerige en stroperige vloeistof op die gevulkaniseerd kon worden. En het resultaat was rubber dat zo goed als nieuw is.’

Het patent op deze ontdekking wordt al gebruikt door New Born Rubber, een bedrijf in Grootegast. Zij maken er slippers en opvouwbare fietsmandjes mee. ‘Ik verdien er niet echt veel aan, en het werk dat ik hierin gestoken heb heeft zelfs mijn productie van wetenschappelijke publicaties een beetje doen afnemen. Maar ik heb een concreet probleem opgelost, en daar ben ik heel gelukkig mee.’

Tekst: FSE Science Newsroom | René Fransen / Foto’s: Reyer Boxem

In Makers van de RUG belichten we elke twee weken een onderzoeker die iets concreets heeft ontwikkeld: van zelfgemaakte meetapparatuur voor wetenschappelijk onderzoek tot kleine of grote producten die ons dagelijks leven kunnen veranderen. Zo dragen RUG-onderzoekers bij aan oplossingen voor grote wetenschappelijke en maatschappelijke uitdagingen. Eerdere portretten van ‘Makers’ vind je op de overzichtspagina.

Techniekonderwijs en -onderzoek maken bij de RUG al decennia deel uit van een breed palet aan sterke disciplines en landelijk werken we steeds intensiever samen met de vier technische universiteiten.

Meer informatie

Meer nieuws

-

17 februari 2026

De lange zoektocht naar nieuwe fysica

-

10 februari 2026

Waarom slechts een klein aantal planeten geschikt is voor leven