Van afvalstoffen naar duurzame kerosine

Erik Heeres is geen klassieke wetenschapper. De geboren Pekelder ontwikkelde zich van tiener met een scheikundedoos tot succesvol projectleider van grote Nederlandse en Europese onderzoeksconsortia. Nog altijd heeft de hoogleraar Chemische Technologie een warm hart voor een duurzaam en innovatief Noord-Nederland.

Tekst: Riepko Buikema, afdeling Communicatie RUG; foto’s: Henk Veenstra

‘Hier, lees de appjes maar’, zegt Erik Heeres terwijl hij enthousiast zijn telefoon overhandigt. Trots toont hij de foto’s van een stel moderne stoelen, volledig gemaakt uit natuurlijke grondstoffen van Groninger bodem: hennep, magnesium en aardappelen. Binnenkort in het assortiment van een lokale winkelier. ‘Een zichtbaar product, aansprekend voor de mensen. Dan komt het eindresultaat van ons werk ineens dichtbij. Dat vind ik zelf erg leuk.’

Geboortegrond

De stoelen zijn een tastbaar resultaat van de Innovatiehub Oost-Groningen waarvan de Pekelder hoogleraar een van de initiatiefnemers is. ‘Ken je dat, de IHOG? Daar moet ik echt even iets over vertellen.’ Samen met zijn broer André (lector Biobased Chemie aan de Hanzehogeschool), de hoogleraren Aard Groen en Willem Jonker en ondernemer Jakob Zwinderman probeert Heeres de economie van hun gedeelde geboortegrond te versterken. Vertrekpunt: wat kunnen we doen met de grondstoffen en bijproducten van onze regio?

Heeres: ‘We zoeken mogelijkheden om de bouwstenen hennep, zouten en zetmeel te combineren. Aan platen van hennep voegen we nu bijvoorbeeld magnesiumzouten toe om ze brandwerend te maken, waarna we alles samenlijmen met aardappelzetmeel. Een prachtig biobased product om de bouw te verduurzamen. Zo geven we samen met Avebe, Hempflax en Nedmag een boost aan de regio.’

Groene Groninger

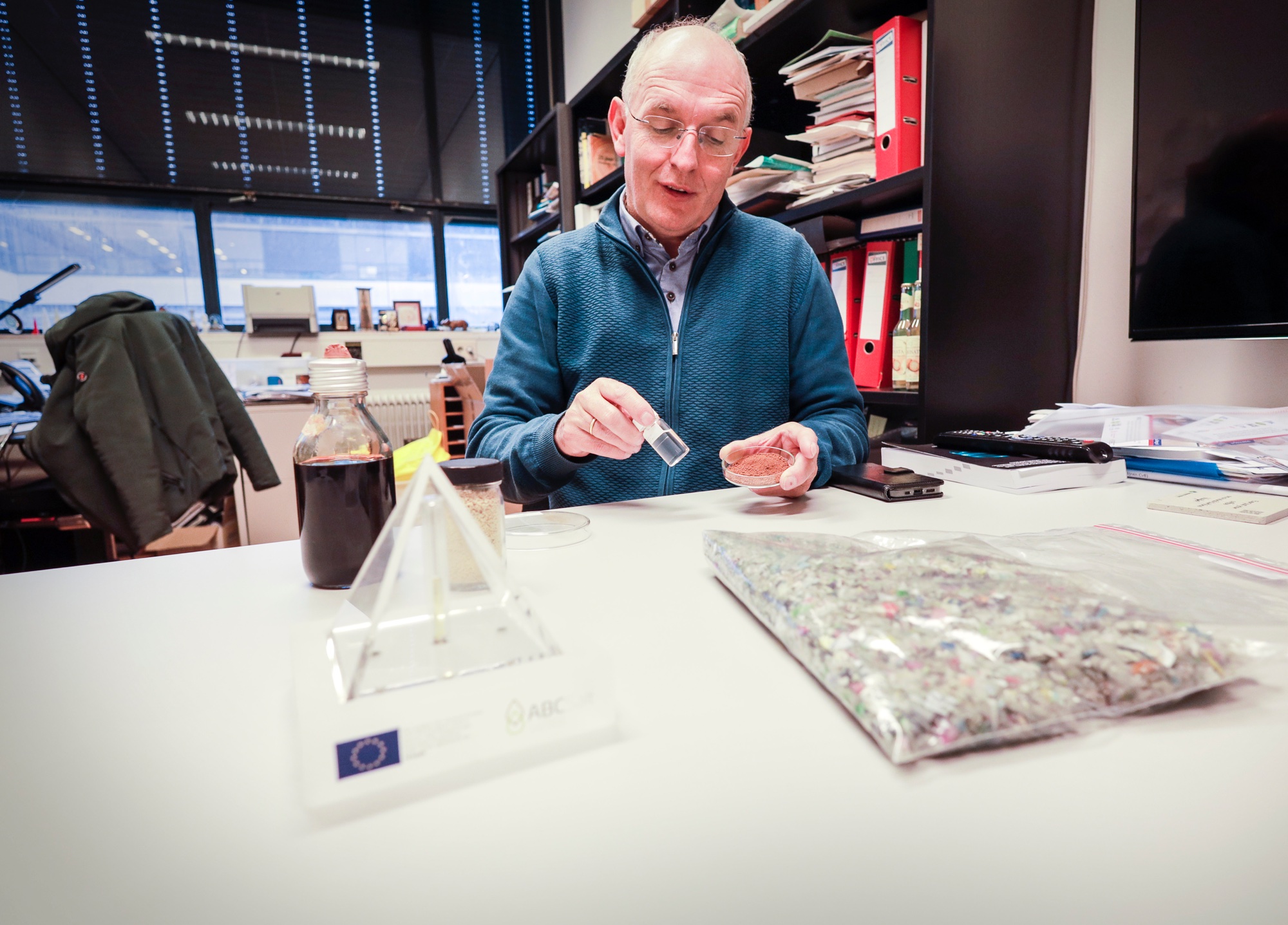

Samen met zijn broer ontving Erik Heeres al eens De Groene Groninger, een onderscheiding voor wie zich bijzonder inzet voor de omschakeling naar duurzame energie en grondstoffen. Dat betekent niet dat het werk van de hoogleraar Chemische Technologie zich beperkt tot het noorden. Zo gaf hij leiding aan het grote Europese project ABC Salt, dat resulteerde in een veelbelovende manier om afvalstoffen uit de papier- en pulpindustrie om te zetten in duurzame diesel en kerosine. ‘Heel succesvol’, glundert Heeres, terwijl hij wijst op een kek buisje vliegtuigbrandstof op zijn bureau, bedoeld als ‘bewijsmateriaal’ voor zijn subsidieverstrekkers.

‘Onze bron was lignine, een houtstof. Voor onze chemische truc met gesmolten zouten hebben we drie patenten aangevraagd.’ Het is precies wat Heeres drijft. ‘Het is ontzettend leuk om te pielen op moleculair niveau, daar kun je zelfs de Nobelprijs mee winnen’, zegt Heeres met een knipoog naar collega Ben Feringa. ‘Maar ik vind het nog mooier als iets op redelijk korte tijdschaal toepasbaar wordt. De kans is heel groot dat deze vondst over tien jaar wordt gebruikt in de industrie.’

Zoektocht

Ook op zijn bureau: een zakje plastic snippers, eveneens een startmateriaal voor zijn zoektocht naar nieuwe chemische processen. ‘De interesse voor plastic is enorm toegenomen de afgelopen jaren. PET-flessen recyclen gaat relatief makkelijk, dat geldt ook voor tapijten. Maar bij isolatiemateriaal uit koelkasten ligt dat veel ingewikkelder. Dat bestaat uit polymeren die veel moeilijker zijn af te breken, dat geldt ook voor tachtig procent van ons verpakkingsmateriaal. Wij zoeken naar manieren waarmee je die koolstofbronnen toch kunt hergebruiken als grondstof voor de chemische industrie of voor het oorspronkelijke product.’

Gereedschapskist

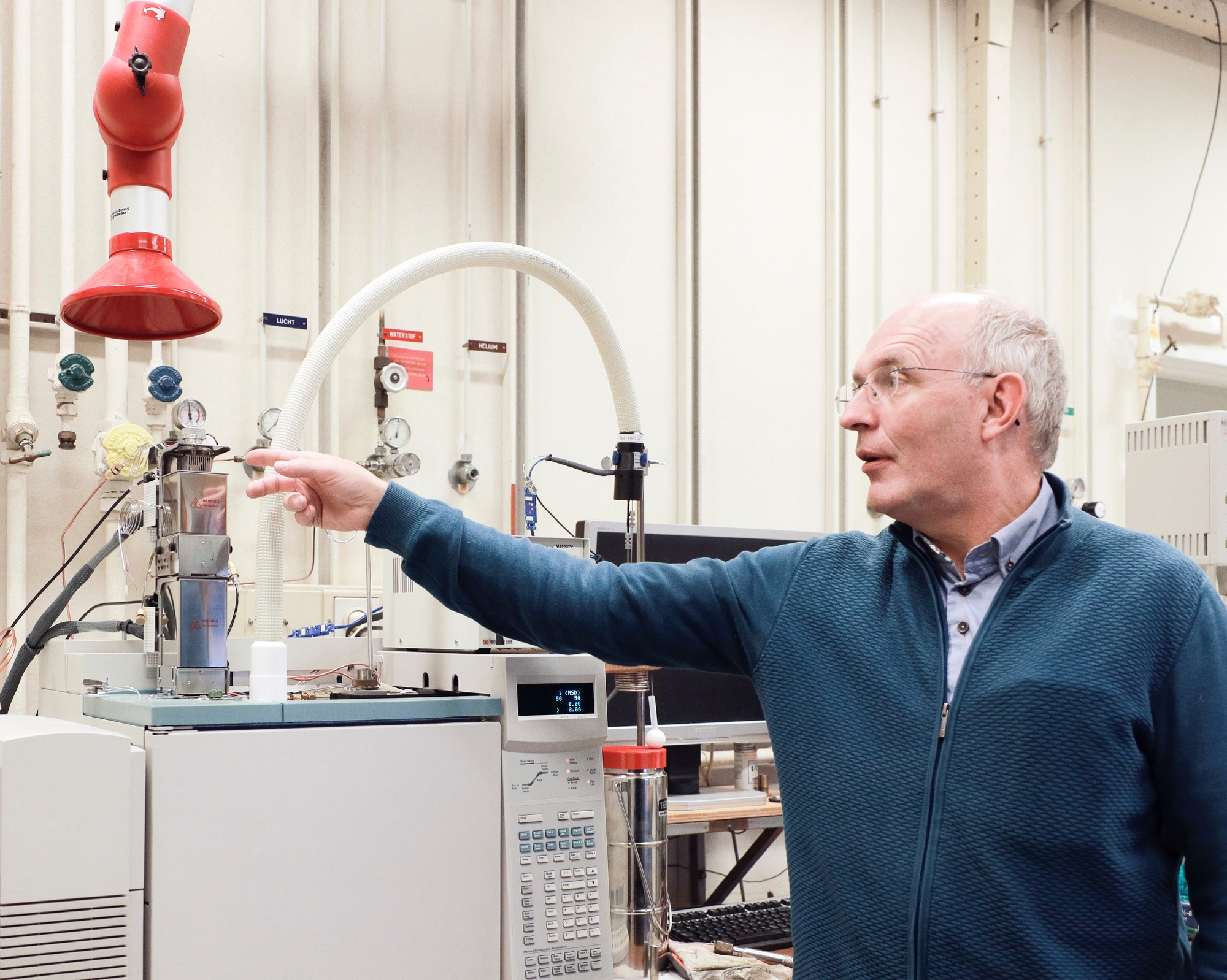

In zekere zin is Heeres dan weer dat jongetje uit Pekela, een jaar of tien oud, thuis experimenterend met zijn scheikundedoos. ‘De kerntechnologie van onze vakgroep is pyrolyse. We ontleden koolstofhoudend materiaal door het te verhitten tot hoge temperaturen zonder dat er zuurstof bij kan komen. Als je houtsnippers opwarmt naar 400 tot 500 graden dan kun je de biopolymeren afbreken en verdampen. Die damp kun je condenseren en als je dat opvangt heb je eigenlijk vloeibaar hout. Hier, ruik maar, het is net rookworst.’

Iets verderop in de gang, tijdens een gepassioneerde rondleiding langs de chemische installaties in het lab, vertelt Heeres over de onbegrensde mogelijkheden. ‘Je kunt oneindig spelen met de temperatuur, met de startmaterialen. Op kleine schaal proefjes doen. Onze gereedschapskist zit vol katalysatoren, stofjes die bepaalde chemische reacties versnellen. Er zijn eindeloze combinaties mogelijk, met uiteenlopende opbrengsten uiteraard.’

Samen de wereld in

De tijd dat Heeres zelf aan de knoppen draaide is voorbij. ‘Ik genoot altijd van het labwerk, maar ben er te duur voor geworden’, zegt hij lachend. ‘Mijn rol is nu meer om vindingen uit te dragen naar buiten, te zorgen dat we de industrie helpen nieuwe processen te gebruiken, om onderzoeksprojecten te coördineren. Ook leuk.’

Zeker als dat samen kan met broertje André. ‘Een ander type mens. Ik ben analytisch, hij is creatiever. We zijn complementair, dat helpt enorm in de samenwerking.’ De broers Heeres bundelen hun krachten onder meer in de Smart & Circulair Alliance, een netwerk waarin RUG, Hanze en de industrie rond Delfzijl, Emmen, Eemshaven en Drachten proberen de spectaculaire ontwikkelingen binnen smart industry en circulair produceren te verenigen.

‘Er komt veel op bedrijven af, in 2030 moeten ze grotendeels groen zijn. Ons ultieme doel is echt iets voor elkaar te krijgen voor de regio. Om mkb-bedrijven te helpen hun groene doelen te halen, door faciliteiten bieden, kennisuitwisseling te stimuleren, opleidingen aan te bieden. We hebben de externe adviseurs Elzo de Lange en Freek Lagerweij ingehuurd om die plannen verder uit te werken.’

Onconventioneel

Ik ben geen klassieke wetenschapper, benadrukt Heeres ten overvloede. ‘Ik heb een fantastische dag wanneer een PhD-student een leuke vondst doet en ook als we samen ons doel bereiken in een EU-project, als zo’n internationaal team leidt tot een concrete opbrengst. Maar een meeting met Elzo en de industrie, waarin iedereen vol energie is om samen te werken, daar kan ik ook erg blij van worden.’

Heeres heeft de zin nog niet uitgesproken of een ondernemer uit zijn netwerk belt met de vraag of hij wil meedoen aan een aanvraag voor middelen uit het Just Transition Fund, waarin de EU 230 miljoen beschikbaar stelt om de economie in Noord-Nederland te verduurzamen en te vergroenen.

Moedig voorwaarts

Of Heeres optimistisch is over die duurzame toekomst? ‘We hebben geen keus. Onze regio biedt gewoon heel veel kansen, maar die moet je wel pakken. We hebben mooie industrieën, een sterke landbouw. Dit gebied was in het verleden een van de rijkste van het land: aardappelmeelindustrie, scheepsbouw, turfwinning. Op die manier moeten we aan de slag: kijk naar wat je wél kunt!’

Meer nieuws

-

10 februari 2026

Waarom slechts een klein aantal planeten geschikt is voor leven

-

09 februari 2026

Kunnen we de aarde de andere kant op laten draaien?