Research

The Van der Giessen group is interested in all aspects of mechanical behaviour at size scales of micrometers and below. This includes the mechanics of engineered devices or biological entities, as well as the relationship between internal structure of a material (the microstructure) and its properties. We apply theory and a variety of computational techniques including molecular dynamics, dislocation dynamics, Monte Carlo methods and finite element methods. Size dependence is a common theme.

Currently, my group is mainly working on three research areas:

(1) Biophysics (in collaboration with the Onck group)

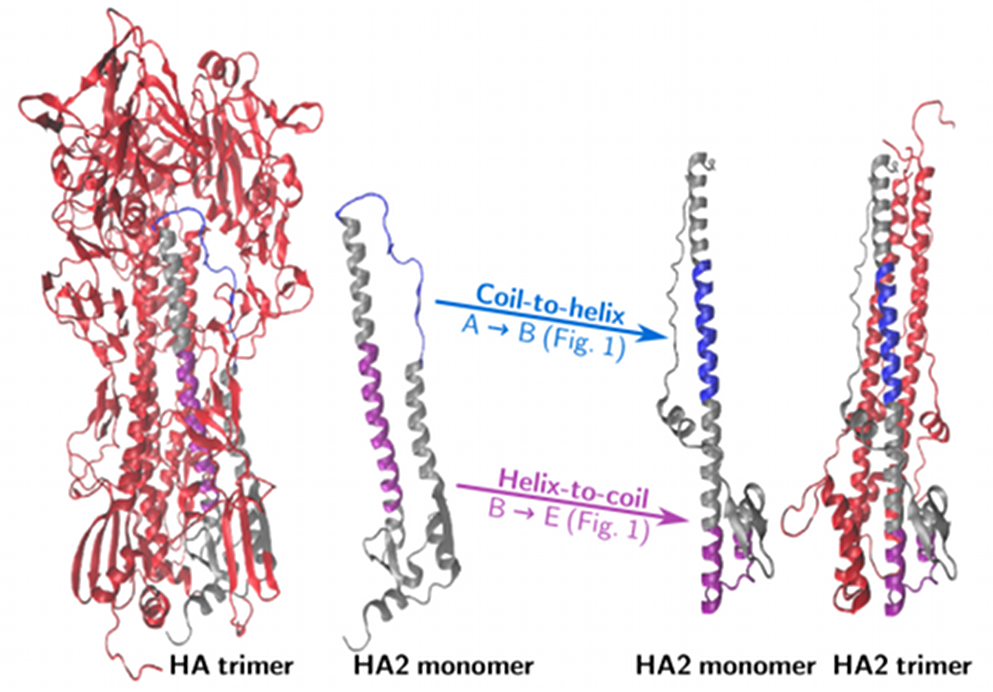

In this work we study fundamental processes in the cell in order to elucidate the biophysical mechanisms that are responsible for transport of biomolecules through the nuclear pore complex, the structure-property relations of the cytoskeleton, protein aggregation in neurodegenerative diseases and the molecular mechanics of influenza viral fusion. For more details, follow this link.

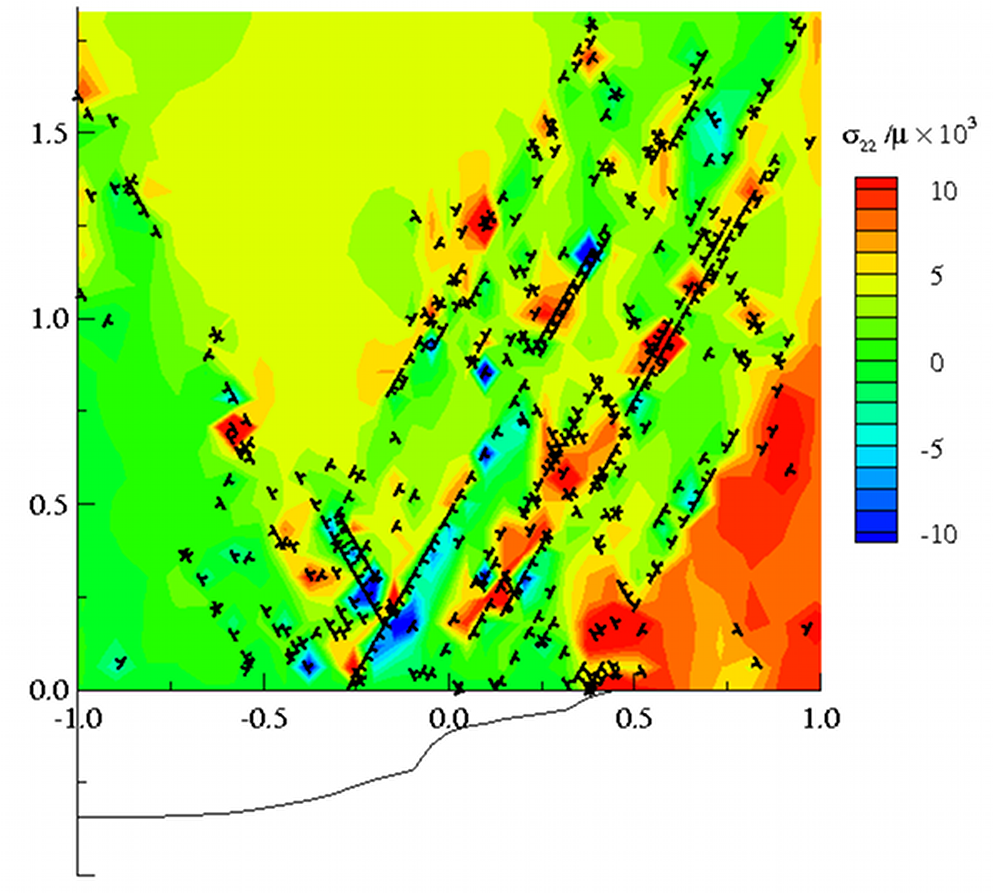

(2) Discrete dislocation plasticity

Discrete dislocation plasticity provides an inherently size-dependent description of plastic deformation at size scales of tens of micrometers and smaller by tracking the dynamics of dislocations. We use our own dislocation dynamics codes to study microscale plasticity in small specimens, in thin films, in the small asperities in rough surface contact and friction, and plasticity associated with fracture processes in complex microstructures. For more details, follow this link.

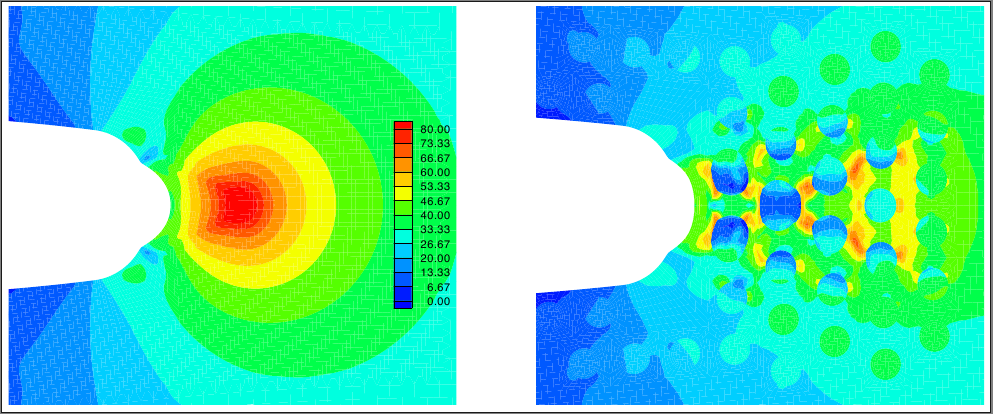

(3) Polymer blends and nano-composites

Many polymers would not find structural application if they were not blended or reinforced. In this work we aim at understanding the competition between different deformation mechanisms and fracture processes in polymer composites that are blended with fillers of micrometer or nanometer dimensions in order to improve the fracture toughness and impact resistance.

| Last modified: | 25 September 2017 12.16 p.m. |