Science for Society | Rubber recycling possible thanks to revolutionary method

Scientists work day by day on solutions to a variety of problems. From new drugs to smart farming techniques, our research helps society move forward. But this is not always immediately visible. In this series, we use stories about impactful innovations, products and ideas to show that science works!

Tekst: Thomas Vos, Corporate Communicatie RUG

The Ben Feringa Impact Award (category researchers) was presented to him on 13 May: Francesco Picchioni, professor of Chemical Technology (FSE). The reason for his award? An important innovation that allows rubber recycling without loss of quality. Start-up New Born Rubber from Grootegast is already eagerly using his method for the production of flip flops and bicycle baskets.

From large-scale deforestation (which is almost as bad as palm oil production) to decreased biodiversity and severe air and water pollution: rubber production has a clear and negative impact on the environment and on human and animal health. Moreover, after usage, a lot of rubber, such as car tires, ends up in large, non-biodegradable landfills or in polluting incinerators.

Recycling is difficult

But recycling rubber is difficult: reusing old rubber requires breaking down sulphur bridges: chemical bonds of atoms that attach liquid rubber strands together. But this also creates fractures in the rubber strands themselves. And that makes for low-quality rubber.

Breaking into pieces

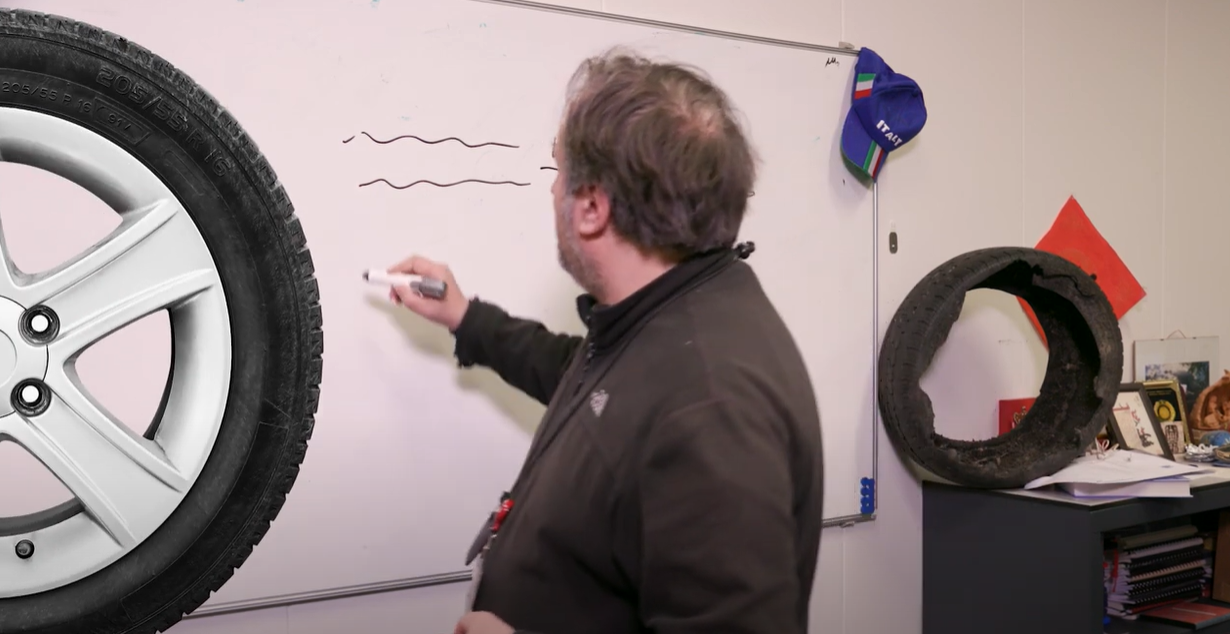

Researchers from around the world have been trying to develop an applicable method for some time. Professor of Chemical Technology Francesco Picchioni decided to take a different approach than his colleagues: ‘I'm rather contrarian and thought: what if I just break those rubber strands into small pieces and come up with something to mend that?’

New technique

Picchioni developed a mechanical technique to break the rubber into pieces. Then, by randomly sticking the broken pieces together using a chemical substance, a viscous liquid is created that can be vulcanized again. In the process, the rubber is processed at relatively high temperature, creating an extremely strong bond. Picchioni: ‘The whole process, from breaking the rubber strands to vulcanization, results in rubber that is as good as new. You can use that to make all kinds of new, high-quality products.’

New Born Rubber

Start-up New Born Rubber in Grootegast is already eagerly making use of Picchioni's invention. The company, set up by investors in collaboration with Picchioni and colleagues from the UG, recycles rubber car or bicycle tires. From these, the company then makes flip-flops and trendy bicycle baskets, among other things.

The only one in the world

One of the founders of the start-up, Remko Bloembergen, told Groningen newspaper Dagblad van het Noorden that there is ‘no other company in the world’ that can recycle rubber to such a high standard. And although the business world still has to get used to recycled rubber, if it is up to the founders, it will be used everywhere in a few years.

Picchioni himself does not earn much from his revelation, but he is nevertheless satisfied: 'With this, I have solved an important problem, and that is what matters to me.’

Do you want to know more about Science for Society? Check out the overview page for the previous editions.

More news

-

17 February 2026

The long search for new physics

-

10 February 2026

Why only a small number of planets are suitable for life