Start-up Bioprex Medical makes medical implants safer

With an innovative new coating, researchers from the Zernike Institute for Advanced Materials and the UMCG have found a way to prevent bacterial infection on surgical implants and other medical devices. With their start-up Bioprex Medical, they hope to bring this coating to the market in the next few years.

By Renée Moezelaar

When patients get implants, for instance a new knee or hip, doctors always have to be on the lookout for bacterial infection. No matter how clean they try to work, bacteria will always get through. One to five percent of the implant-patients will develop some kind of infection which can lead to the removal of the implant, serious illness or even death. With a new antibacterial coating, the new start-up Bioprex Medical wants to prevent these infections and make implant surgery saver.

Twenty years

Bioprex Medical was founded by Ton Loontjens, professor emeritus of material science at the Zernike Institute for Advanced Materials. “I have been working on these types of coatings for almost twenty years now”, he says. “But eight years ago I got into contact with Pieter André de la Porte, director of Zorg Innovaties Nederland (Healhcare innovations in the Netherlands), and we started working on a commercial type of coating for medical applications.” The coating Loontjens and his colleagues developed seemed to work well, so they decided to found a start-up: “Our coating has nice properties that suits medical applications, so we decided to take it one step further and try to bring it to the market.”

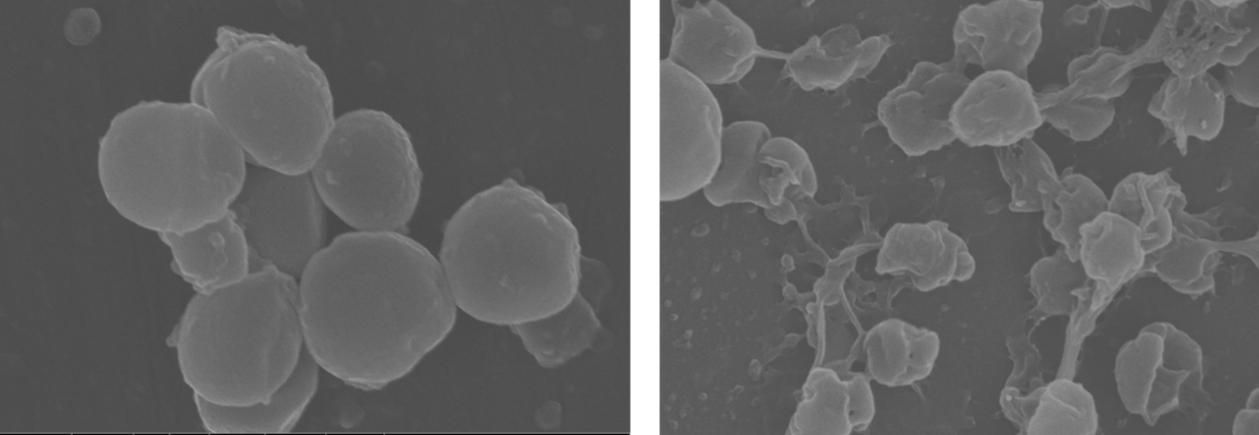

The immobilized coating works on the basis of quaternary ammonium moieties that can kill bacteria when they come into contact. The main component is an unique hyperbranched polymer that the researchers developed themselves. “At the end of each branch we can add polyamines, that can be quaternized and turned into quaternary ammonium groups”, Loontjens explains. “Because there are a lot of branches, there are a lot of these groups and this gives a high charge density. We found that such a high density attracts nearby bacteria and kills them on contact.”

Attached

The coating is covalently attached to the surface of the implant with a coupling agent, which gives a high strength and stability. Loontjens: “Another advantage is that the hyperbranched polymer is hydrophobic, so water can’t reach the surface of the implant which prevents hydrolysis of the bonding to the surface of the implant.” The whole process of applying the coating does need some more work. “Application of the initial academic coating used to take about eight days”, Loontjens says. “We have reduced that to eight hours now, but our aim is to apply it even faster.”

The start-up Bioprex Medical should help the researchers to make the leap towards the market. “We try to optimize the coating as far as we can”, Loontjens says. “And meanwhile we are discussing our technology with companies that can apply coatings and companies that make medical implants.” Even though there is still work to be done, Loontjens is optimistic about their chances: “All parties are very interested in bringing down the chances of infections during surgery, which is of course a very important goal that could actually save lives. So, we hope that in about three years we will have a first Bioprex-coated product on the market.”

For more information contact Ton Loontjens.

More news

-

15 September 2025

Successful visit to the UG by Rector of Institut Teknologi Bandung