Flying on wood dust

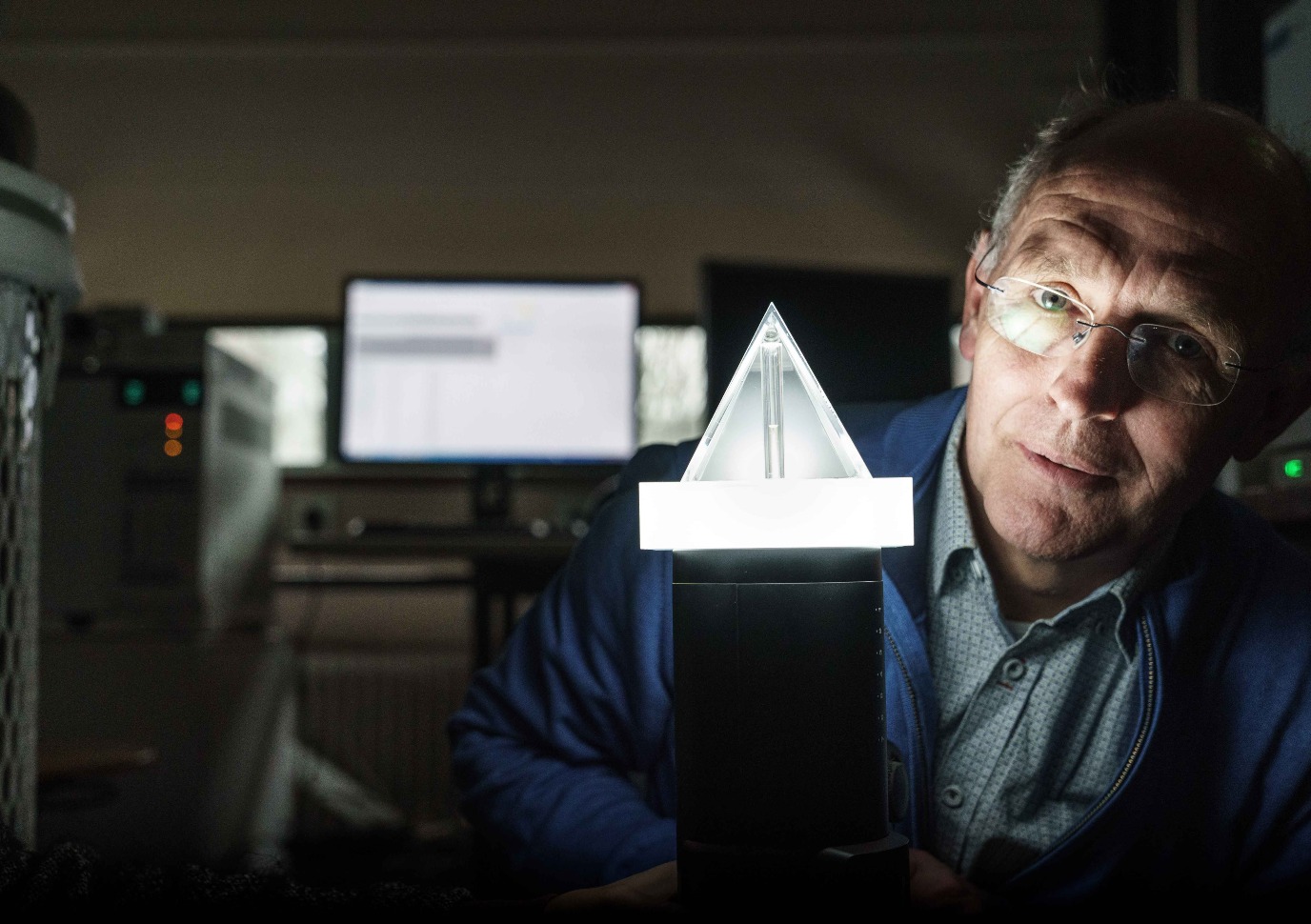

Inside the pyramid is a tube of sustainable aviation fuel made from lignin (wood dust). That’s a residual product from the paper industry that is usually burnt on site. ‘Burning is actually the last thing you want to do in the life cycle of a material,’ explains Professor of Chemical Engineering Erik Heeres. ‘We want to increase the value to that lignin, in this case by turning it into a biofuel.’

Lignin is a large molecule. In order to turn it into usable fuel, you need to chop it into smaller bits and remove some unwanted components. Heeres: ‘It was a matter of finding the right substances to speed up that process, but also finding the right process conditions, such as temperature, pressure, and so on, and that requires a lot of research.’

Moreover, there is a long list of properties that aviation fuel has to meet. Heeres sums up: ‘There are standards for its boiling point, viscosity, sulphur content...’ He shows the lab set-up with which his group finally managed to make the biofuel, although it does not yet meet all the requirements on the wish list. ‘We are currently writing proposals for follow-up projects’, adds Heeres.

The lab set-up comprises two impressive devices, each of which handles a phase of the production process. In phase one, the lignin is heated to high temperatures without oxygen. This results in lignin oil, a brown stuff that smells like smoked herring, but without the fishy smell. A second, equally impressive device breaks the lignin into small parts and extracts any unwanted substances.

‘We build that equipment ourselves as much as possible,’ Heeres proudly explains. ‘We’re true engineers. We have five technicians in our team. And hey, if a handy PhD student comes along, they can build something themselves.’ And what about that pyramid, did they also build that? ‘We’ve had that made,’ says Heeres. ‘As a keepsake for all the projectpartners.’

Text: FSE Science Newsroom | Charlotte Vlek

Photos: Reyer Boxem

Every two weeks, UG Makers puts the spotlight on a researcher who has created something tangible, ranging from homemade measuring equipment for academic research to small or larger products that can change our daily lives. That is how UG researchers contribute to the solutions for big scientific and societal challenges.

For decades, engineering teaching and research at the UG has been part of a wide array of strong disciplines, and from a national point of view, our collaboration with the four technical universities is becoming more and more intensive.

Previous portraits of Makers can be found on the

overview page

.

More information

Erik Heeres

More news

-

15 September 2025

Successful visit to the UG by Rector of Institut Teknologi Bandung