15 jaar moleculen bouwen tegen tuberculose: op naar laagdrempelige tests voor ontwikkelingslanden

‘Ik ben de man die de moleculen bouwt,’ vertelt Adri Minnaard, hoogleraar Organische Chemie aan de Rijksuniversiteit Groningen. Hij doet al ruim vijftien jaar onderzoek naar tuberculose, en werkt samen met een internationaal en interdisciplinair team. Minnaard bouwt stukjes van de tuberculose-bacterie na. Dat is volgens hem dé route naar een effectiever vaccin en simpele, robuuste diagnostiek.

FSE Science Newsroom | Charlotte Vlek

Update 5 maart 2024: Adri Minnaard en zijn Lipidomics team winnen de Ammodo Science Award voor hun onderzoek naar tuberculose.

Jaarlijks sterven er wereldwijd 1,5 miljoen mensen aan tuberculose, blijkt uit cijfers van de Wereldgezondheidsorganisatie (WHO). En dat terwijl de ziekte te behandelen en te voorkomen is. Vooral in ontwikkelingslanden is het een groot probleem.

Waarom het huidige vaccin niet voldoet

Minnaard: ‘Kort en goed: het BCG-vaccin werkt eigenlijk niet. Een gevaccineerde ontwikkelt wel antistoffen tegen de bacterie, maar kan er toch nog ziek van worden. Bovendien zorgen die antistoffen ervoor dat de meest eenvoudige diagnostiek niet meer bruikbaar is.’

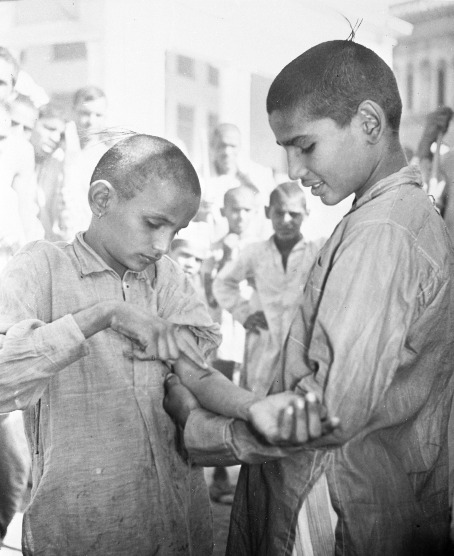

Tuberculose wordt standaard opgespoord met de Mantoux-test: een oppervlakkig prikje in de huid met stukjes van de tuberculose-bacterie. Wie besmet is reageert; het prikje wordt een rood bultje. Maar wie met BCG gevaccineerd is krijgt ook zonder besmetting een rood bultje. Daardoor kun je niet meer zien of iemand die gevaccineerd is, besmet is geraakt.

Een chemische benadering

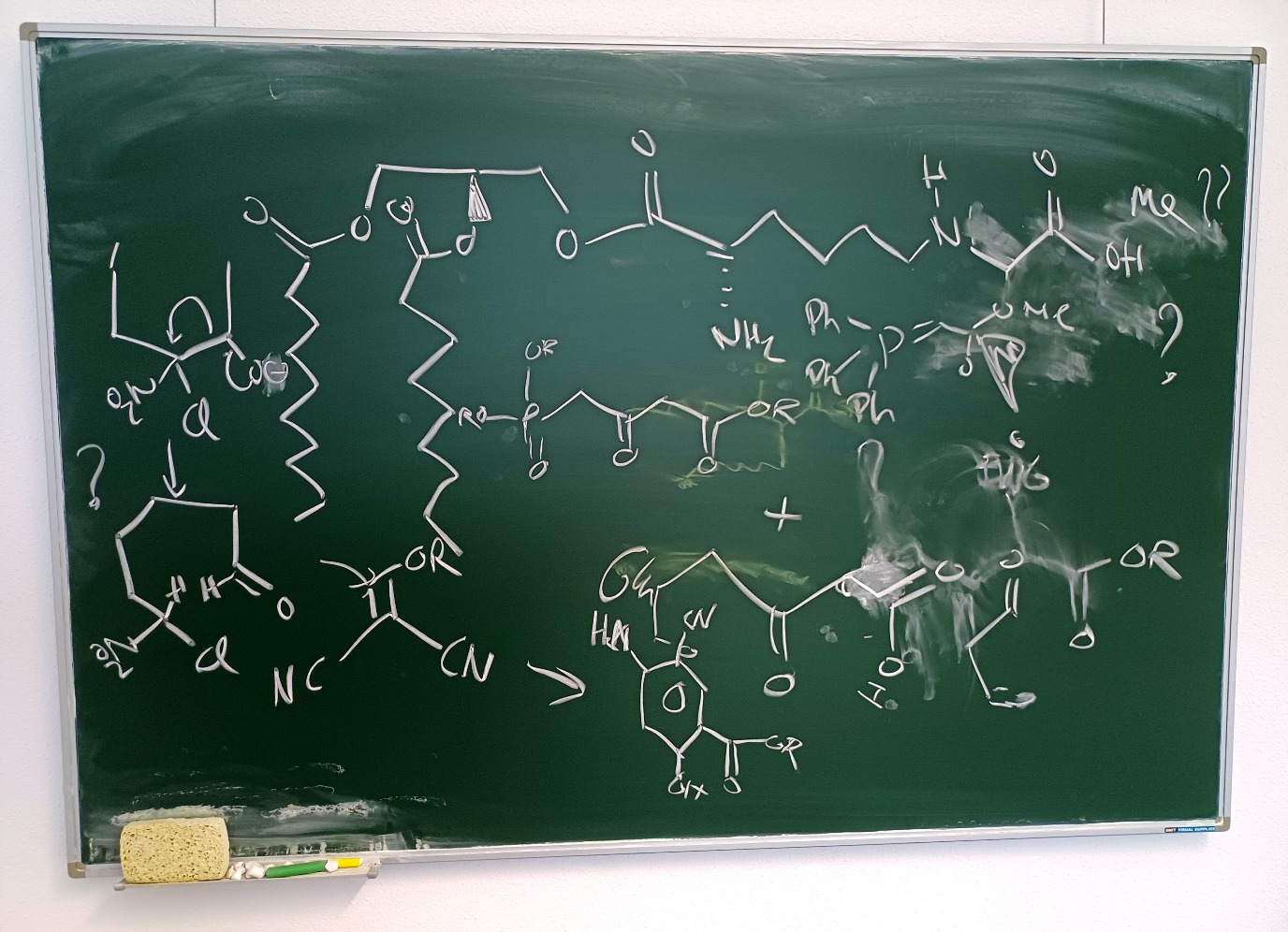

Met chemische technieken kun je precies die stukjes van de bacterie nabouwen die voor het lichaam de rode vlaggetjes zijn om op te reageren.

‘We weten sinds ongeveer 25 jaar dat het lichaam wel in actie komt tegen tuberculose, maar deze reactie is niet sterk genoeg om de bacterie helemaal te overwinnen,’ vertelt Minnaard. Door het lichaam aan een nagebouwd stukje van de tuberculose-bacterie bloot te stellen, zou het alvast de juiste antistoffen kunnen aanmaken.

Met chemische technieken kun je precies die stukjes van de bacterie nabouwen die voor het lichaam de rode vlaggetjes zijn om op te reageren: antigenen. Minnaard licht toe: ‘je kunt precies maken wat je nodig hebt, en je kunt het goed doseren.’

(tekst gaat verder onder de foto)

Moleculen bouwen, hoe gaat dat?

Hoe dit verschilt van het BCG-vaccin

Het afweersysteem herkent een indringer doorgaans aan zijn buitenkant: daar zitten meestal eiwitten die specifiek zijn voor de ziekteverwekker. Eiwitten zijn ook de basis van het BCG-vaccin, en de Mantoux-test toont aan of het lichaam antistoffen tegen die eiwitten heeft aangemaakt.

Maar het lichaam blijkt bij tuberculose ook antistoffen aan te maken tegen de vetachtige stoffen aan de buitenkant van de bacterie: lipiden. En de antistoffen die het lichaam in reactie op die lipiden aanmaakt, zijn heel anders dan de antistoffen dan die het BCG-vaccin opwekt.

Minnaard bouwt zulke lipiden na, met het idee dat het lichaam ze zal herkennen als een stukje van de ziekteverwekker.

Een nieuw vaccin?

In 2013 kreeg Minnaard samen met wetenschappers van Harvard Medical School (VS), het Institute of Pharmacology & Structural Biology (Frankrijk) en Tuberculosis Vaccine Initiative (VK) een onderzoekssubsidie van de Bill & Melinda Gates Foundation om een vaccin te ontwikkelen op basis van lipiden.

Minnaard bouwde de lipiden; zijn wetenschappelijke partners testten het resulterende vaccin op proefdieren. Die lieten inderdaad een afweerreactie zien na toediening van de gebouwde moleculen. Helaas bleken de dieren drie weken later niet beschermd tegen een infectie met tuberculose.

Minnaard: ‘Terugkijkend denk ik dat het lag aan een ingrediënt van ons vaccin waarmee we ervoor wilden zorgen dat het afweersysteem zich de ziekteverwekker langdurig zou herinneren.’ Zo’n middel wordt bij elk vaccin gebruikt, maar is niet voor elke ziekteverwekker gelijk. ‘We hebben natuurlijk verschillende stoffen geprobeerd, maar het juiste middel is gewoon nog niet gevonden.’

Tuberculose-moleculen beschikbaar maken

Op naar een laagdrempelige test

Inmiddels hebben Minnaard en consorten hun aandacht verlegd van een vaccin naar de ontwikkeling van een laagdrempelige test, vooral nuttig voor gebruik in ontwikkelingslanden. Minnaard: ‘Stel je voor, een patiënt komt binnen. Je hebt een plaatje met daarop wat van die kunstmatig geproduceerde lipiden. Wanneer je een beetje bloed van een patiënt over die lipiden giet, kun je zien of er antistoffen tegen de tuberculose-bacterie in het bloed zitten: die blijven plakken.’

Deze test is structureel anders dan de Mantoux-test: het gaat hier om antistoffen die het lichaam maakt in reactie op lipiden, in plaats van antistoffen in reactie op eiwitten. Het probleem dat BCG-gevaccineerden altijd een positieve testuitslag krijgen wordt dus zo omzeild.

Van het lab naar de kliniek

Deze lipiden zijn heel robuust, je kunt ze bij wijze van spreken in een doosje op de achterbank van je auto naar Oeganda rijden

‘Het principe van deze lipide-test werkt, dat weten we inmiddels,’ vertelt Minnaard. De medische partners in het project hebben aangetoond dat een gezuiverde antistof inderdaad blijft ‘plakken’ aan de lipiden die Minnaard heeft gemaakt. De volgende stap is om te kijken of het ook werkt met bloed van proefpersonen, en of de test dan ook bij herhaling betrouwbare resultaten geeft - dat is de fase waar het team nu in zit.

Minnaard ziet grote voordelen voor wereldwijde tuberculose-diagnostiek: ‘Deze test zal ook bruikbaar zijn voor iemand die al gevaccineerd is met het BCG-vaccin, wat in ontwikkelingslanden nog gebruikelijk is. Bovendien zijn deze lipiden heel robuust, je kunt ze bij wijze van spreken in een doosje op de achterbank van je auto naar Oeganda rijden.’

Meer nieuws

-

17 februari 2026

De lange zoektocht naar nieuwe fysica

-

10 februari 2026

Waarom slechts een klein aantal planeten geschikt is voor leven